Dielectric Constant

Temperature

The dielectric constant of lubricating oil is affected by impurities such as water content, wear particles, acid value and base value of the oil. By monitoring the change of dielectric constant with our YTS-D-1 oil condition sensor, we can understand the overall performance trend and obtain the degradation rate of the lubricant. Oxidation can also be used to determine the quality of the oil.

| PARAMETER | RANGE | ACCURACY |

|---|---|---|

| Temperature | -40~120℃ | ±0.3℃(25℃) |

| Dielectric Constant | 1~6 | ±3% |

| (Oil quality) | ||

| Note: Measurement accuracy is the average value of multiple measurements in a static test in a laboratory environment, and there may be deviations under field conditions due to the influence of the external environment. | ||

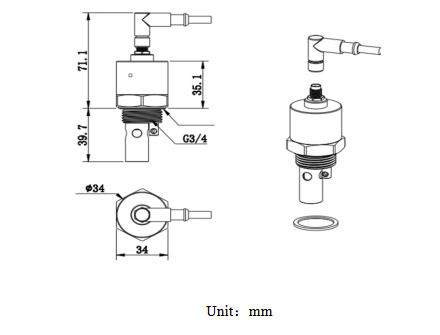

Product Structure: Features:

Features:

- Extremely sensitive to moisture contamination.

- Accurate measurement under harsh operating conditions.

- Well-designed probe structure, robust, reliable and extremely easy to clean.

- Worldwide commercial and technical standards certification.

- Continuous and rapid detection of lubricant dielectric constant value.

- Significant savings on oil change costs and waste oil disposal.

Application:

Yateks sensors are widely applied to monitor the viscosity, density, water content and overall condition of lubricating oils, hydraulic oil, gear oil, transformer oil, petrol, diesel fuels, jet fuel, kerosene, biodiesel, ethanol, chemical reagents, cutting fluids and coating inks.

Our sensors are used in Food processing, Laboratories, Bulk fuel & oil storage facilities, Transportation, Oil refining, Wind Power and coal-fired Power Stations; Aviation, Navigation, Railways, Drilling platforms, Marine, Mining, Crushing & Milling, Process engineering, Steel mills, Pulp & Paper, General manufacturing and within the Printing industry.