Viscosity

Density

Temperature

Dielectric Constant

Water activity in %

Moisture in ppm

YTS 6-in-1 oil condition sensor is a world’s first, using advanced piezoelectric resonant MEMS components, through an integrated high-precision signal sampling and processing unit and combined with advanced algorithms, Yateks automatically detects and reports on;

Sensor measurements:

| PARAMETER | RANGE | ACCURACY |

|---|---|---|

| Temperature | -40~120 ℃ | ±0.3℃(40℃) |

| Viscosity | 1~1000mm²/s(cst) | ±5% |

| Density | 600~1250kg/m³ | ±3% |

| Dielectric constant | 1~6 | ±3% |

| Water activity (Saturation) |

0~1aw | ±0.02aw ( 0~0.6) |

| ±0.03aw (0.6~0.9) | ||

| ±0.04aw (0.9~1) | ||

| Moisture content | 0~5000ppm | ±10% |

| Average of multiple measurements | ||

| Note: The default YTS 6 in 1 sensor uses hydraulic oil 68# to calibrate the moisture content detection. | ||

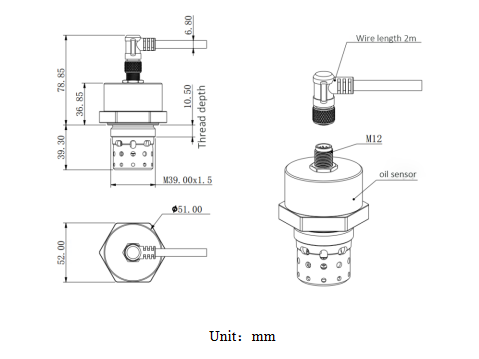

Product Structure:

Features:

High-accuracy measurement of viscosity, density and temperature, with up to six oil condition parameters output via online real-time monitoring;

- Fast response: The data refresh frequency is only 1s.

- The outer casing is made of 316 Stainless Steel and has excellent chemical and pressure resistance.

- Compact structure, easy system integration, on-site calibration of integrated modules.

- Significant savings on oil change costs and waste oil disposal.

Application:

Yateks sensors are widely applied to monitor the viscosity, density, water content and overall condition of lubricating oils, hydraulic oil, gear oil, transformer oil, petrol, diesel fuels, jet fuel, kerosene, biodiesel, ethanol, chemical reagents, cutting fluids and coating inks.

Our sensors are used in Food processing, Laboratories, Bulk fuel & oil storage facilities, Transportation, Oil refining, Wind Power and coal-fired Power Stations; Aviation, Navigation, Railways, Drilling platforms, Marine, Mining, Crushing & Milling, Process engineering, Steel mills, Pulp & Paper, General manufacturing and within the Printing industry.